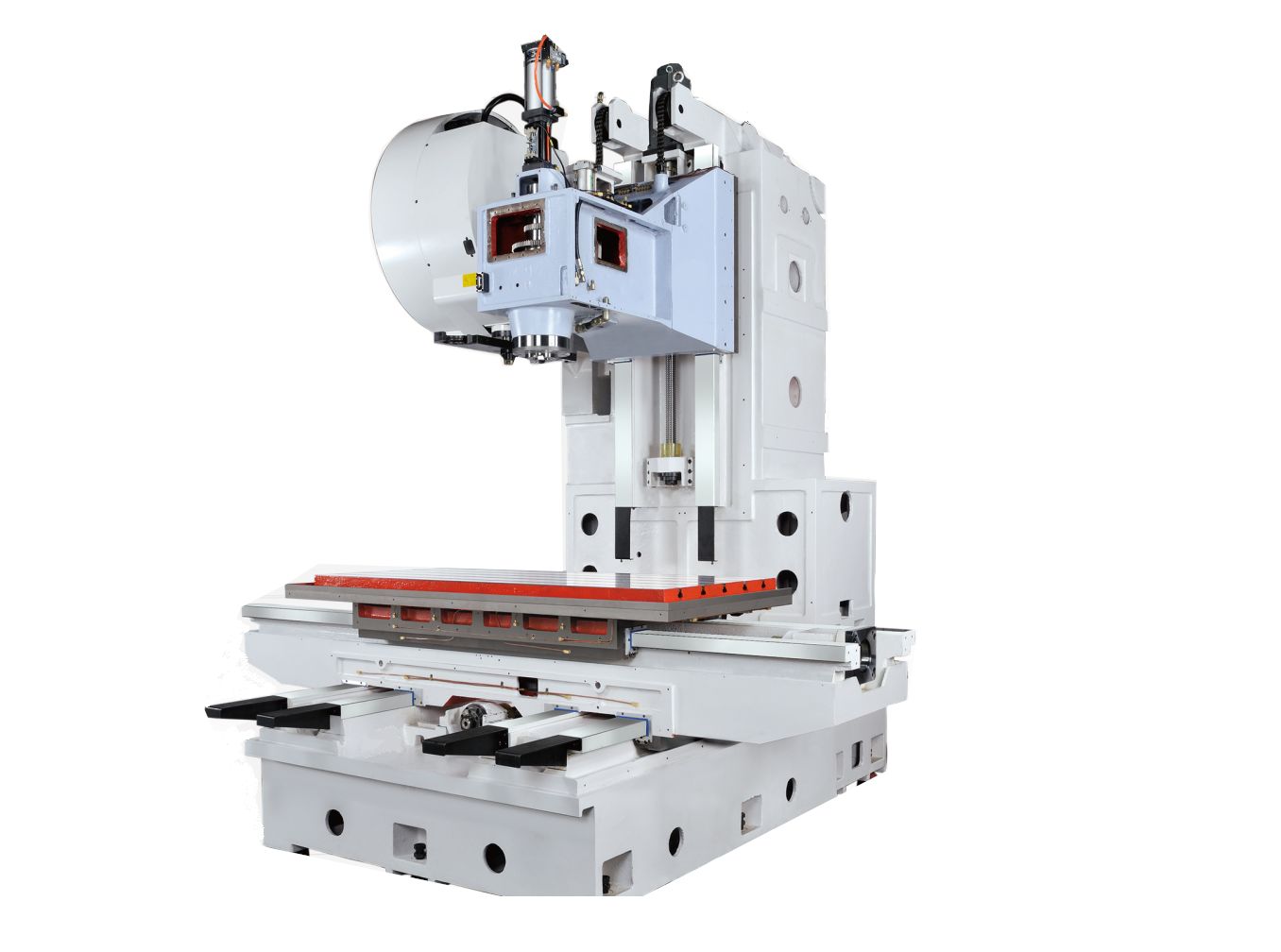

VTJ-1880

Category: CNC Vertical Machining Center

All new super rigid 4 guide ways base structure design.

Powerful, stable, accurate, & best heavy duty machining center.

- All major parts are built with high tensile Meehanite cast irons which provide outstanding wear-resistance and rigidity.

- Extra-widened column base design with ATC support using high standard FEA to provide superior stability during all kinds of applications

- Innovative extra-widened 4 box-way design base provides best support for machine dynamic accuracy.

- Gear Driven #50 spindle

- Extra size work table design with chip-coolant-collected cistern for easy operation set up.

| Specification | |

|---|---|

| Travel X Axis | (1800mm) 70.87" |

| Travel Y Axis | (800mm) 31.5" |

| Travel Z Axis | (800mm) 31.5" |

| Distance from Spindle to Column | (900mm) 35.43" |

| Distance from Spindle Nose to Table | (200-1000mm) 7.8" - 39.37" |

| Table Dimension (Length x Width) | (2000x800mm) 79" x 31" |

| Maximum Loading | (2200Kg) 4,840 lb |

| T-Slot Width | (18mm) 0.71" |

| Spindle Taper | CAT-50 |

| Spindle Motor | (18.5/22KW) 25/30HP |

| Spindle Speed (RPM) | 6000RPM |

| Spindle Driven | High Low Speed Gear Head |

| Rapid Traverse X, Y | (15000mm/min) 591ipm |

| Rapid Traverse Z | (12000mm/min) 472ipm |

| Cutting Feed Rate | (12000mm/min) 472ipm |

| Tool Selection | Shortest Path, Bi-Direction random type |

| Magazine Capacity | Arm Type 32 (Opt. 40) |

| Maximum Tool Dia. | (127mm) 5" |

| Maximum Tool Length | (350mm) 13.78" |

| Maximum Tool Weight | (15Kg) 33 lb |

| Floor Space L x W x H | (4400x2900x2900mm) 173"x114"x114" |

| Power Requirement | 220V, 3 Phase, 60Hz, 40KVA, 100Amp |

| Machine Weight | (15000Kg) 33,000 lb |

All Specification are subject to change without prior notice

| Standard Accessories | Optional Accessories |

|---|---|

| Spindle Gear Head with Hi-Lo Gear | Data Server 2 GB (DNC) |

| Spindle Oil Refrigeration Unit | Chain Type Chip Conveyor & Cart |

| Fanuc Oi-MF Plus, 10.4" Color LCD | Coolant Through Spindle 300PSI Pump |

| 2 MB Memory | High Pressure Coolant System |

| PCMCIA Slot for Memory Expansion | Arm Type 40 Tool ATC |

| Hardened Ground Box Ways on X, Y & Z | 4th Axis Complete |

| Dual Spiral Type Chip Auger | Fanuc 31i |

| Powerful Chip Flush System | 5th Axis Trunnion Table |

| Spindle Air Blast & Cutting Air Blast | Auto Tool Measuring System |

| Arm Type 32 Tool ATC | |

| Auto Lubrication System | |

| 4th Axis Interface Cable Ready | |

| Hand Held Coolant & Air Nozzle | |

| Fanuc & Machine Manual |