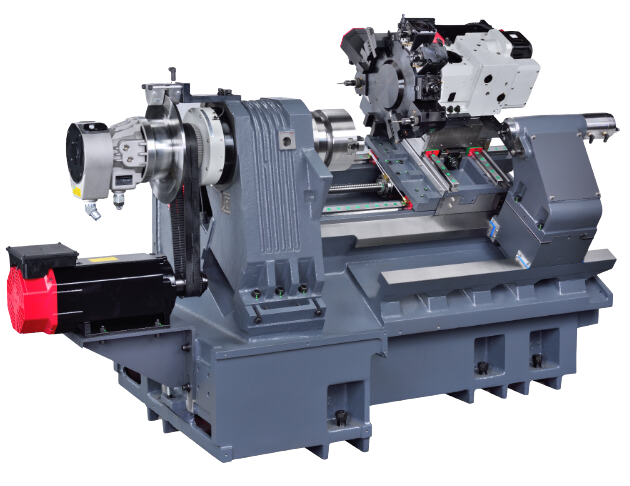

ML-600S

Category: CNC Turning Center

VIDEO DEMO

ML-600S CNC Lathe is a high performance turning center that combines traditional slant bed design with the speed and accuracy of linear ways. The ML-600S is suitable for high production as well as low volume prototype and mold work. The alpha 30ip spindle motor is designed for high torque at low RPM for heavy roughing and drilling, and 3500 RPM maximum speed with full horsepower for quick acceleration / deceleration, less vibration, and extraordinary finishes.- Compact size 231″ x 77″ maximize shop floor space.

- Swivel-type operators panel for quick, convenient set-ups.

- Latest three point support spindle design offers maximum rigidity and precision.

- Rapid traverse rates of 1,180 IPM through linear way design techniques.

- Net weight over 11,968 lbs. provides solid machining operation.

- Available with 8″ or 10″ Hydraulic chuck.

| Specification | |

|---|---|

| Swing Over Bed | (600mm) 23.62" |

| Swing Over Cross Slide | (450mm) 17.72" |

| Maximum Turning Diameter x Full Length | (420mmx560mm) 16.54" x 22" |

| Distance Between Center | (629mm) 24.76" |

| Travel X Axis | (230mm) 9.05" |

| Travel Z Axis | (600mm) 23.62" |

| Rapid Travel X, Z | (30m/min) 1,180ipm |

| Bar Capacity | (78mm) 3.07" |

| Spindle Bore | (91mm) 3.58" |

| Spindle Nose | A2-8 |

| Spindle Motor | (15/18.5KW) 20/25HP |

| Spindle Speed | 3500RPM |

| Spindle Bearing Diameter | (120mm) 4.72" |

| No. of Station | 12 |

| Turning Tool Shank Size | 1" |

| Boring Bar Holder Size | 1.75" |

| Tailstock Quill Diameter | (85mm) 3.35" |

| Tailstock Quill Travel | (367mm) 1.97" |

| Tailstock Quill Taper | M.T.4 |

| Floor Space (L x W x H) | (2870mmx1953mmx1844mm) 231"x77"x 72.60" |

| Machine Weight | (5430kg) 11,968 lb |

| Power Requirement | 220V, 3 Phase, 60Hz, 100Amp |

All Specification are subject to change without prior notice

| Standard Accessories | Optional Accessories |

|---|---|

| 10" 3 Jaw Hydraulic Chuck | Live Tooling with C Axis |

| 12 Station Hydraulic Turret | Auto Tool Presetter |

| 6 Set of Boring Bar Holder & 2 OD Holder | Auto Door Open / Close |

| 6 Set of Wedge Type Tool Clamps | Parts Catcher |

| One Set of Hard Jaw & Soft Jaws | Bar Feeder Interface |

| Manual Guide 0i & Manual Tool Setter | Royal Live Center |

| Chain Type Chip Conveyor & Cart | Royal 5C Collet Chuck |

| Programmable Tailstock Quill | Royal 16C Collet Chuck |

| Auto Lubrication System | Royal 3J Collet Chuck |

| Heat Exchanger for Electrical Cabinet | Steel Soft Jaw for 10" Chuck |

| Operator, Maintenance, Electrical & Part Manual | Y Axis |

| Fanuc Operator & Maintenance Manual | Sub Spindle |