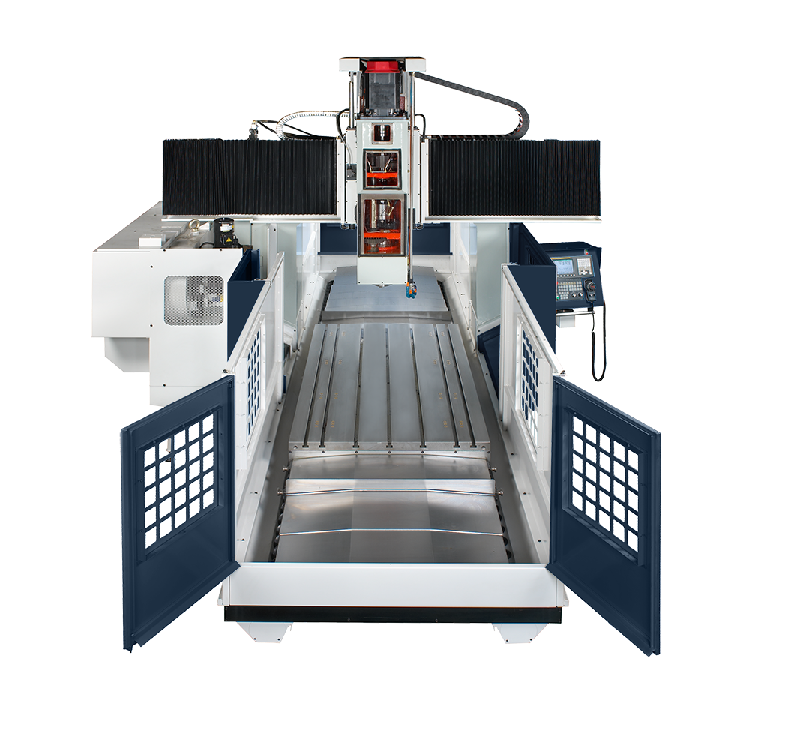

FG-2215L

Category: CNC Bridge Type Machining Center

VIDEO CUTTING

VIDEO HEAD CHANGE

FG series bridge type machining center is designed and produced based on intensive machining experiences of Twinhorn, and concept of user-friendly. With high standard accuracy, superior rigidity and best flexibility application design, FG series is excellent for large-scale parts, mold, mold base as well as aerospace components machining.

- Travels X axis 87" to 244" Y axis 59" to 122"

- Extended head stock design provides better clearance and wider range of cutting capacity.

- Best for huge deep mold and heavy duty machining, High/low gear provides greater cutting rigidity and machining efficiency.

- Special designed alloy steel guide way with HRC60 harden processed, plus steel double roller were used on Y axis to provide a maintenance free guide way structure to ensure smooth movement, stable accuracy and extended machine precision life cycle.

- Build-in type spindle 12000Rpm / 15000Rpm (Opt.) / 20000Rpm (Opt.) equipped with high rigidity precise ceramic bearing, Oil mist for bearing lubrication and Oil refrigeration unit for spindle bearing.

| MODEL | FG-2215L | FG-2715L | FG-3215L | FG-4215L |

|---|---|---|---|---|

| Travel X Axis | (2200mm) 87" | (2700mm) 106.30" | (3200mm) 126" | (4200mm) 165.35" |

| Travel Y Axis | (1500mm) 59" | (1500mm) 59" | (1500mm) 59" | (1500mm) 59" |

| Travel Z Axis | (760mm) 30" | (760mm) 30" | (760mm) 30" | (760mm) 30" |

| Rapid Feed Rate X Axis | (20m/min) 787ipm | (15m/min) 590ipm | (15m/min) 590ipm | (15m/min) 590ipm |

| Rapid Feed Rate Y Axis | (20m/min) 787ipm | (20m/min) 787ipm | (20m/min) 787ipm | (20m/min) 787ipm |

| Rapid Feed Rate Z Axis | (15m/min) 590ipm | (15m/min) 590ipm | (15m/min) 590ipm | (15m/min) 590ipm |

| Cutting Feed Rate X & Y Axis | (10m/min) 394ipm | (10m/min) 394ipm | (10m/min) 394ipm | (10m/min) 394ipm |

| Table Dimension | (2000x1200mm) 78.74"x47.24" | (2500x1200mm) 98.43" x 47.24" | (3200x1200mm) 126" x 47.24" | (4200x1200mm) 165.35" x 47.24" |

| Maximum Loading | (4000Kg) 8,800 lb | (5000Kg) 11,000 lb | (6000Kg) 12,200 lb | (8000Kg) 17,600 lb |

| Distance from Spindle Nose to Table | (200-960mm) 7.87" - 37.8" | (200-960mm) 7.87" - 37.8" | (200-960mm) 7.87" - 37.8" | (200-960mm) 7.87" - 37.8" |

| Distance from Spindle Center to Column | (340mm) 13.39" | (340mm) 13.39" | (340mm) 13.39" | (340mm) 13.39" |

| Distance between Column | (1500mm) 59" | (1500mm) 59" | (1500mm) 59" | (1500mm) 59" |

| Spindle Taper | CAT-40 | CAT-40 | CAT-40 | CAT-40 |

| Spindle Motor | (11/18.5Kw) 15/25Hp | (11/18.5Kw) 15/25Hp | (11/18.5Kw) 15/25Hp | (11/18.5Kw) 15/25Hp |

| Spindle Speed | 12000 RPM (Opt. 15000, 20000 Rpm) | 12000 RPM (Opt. 15000, 20000 Rpm) | 12000 RPM (Opt. 15000, 20000 Rpm) | 12000 RPM (Opt. 15000, 20000 Rpm) |

| Magazine Capacity | Arm Type 32 Tool | Arm Type 32 Tool | Arm Type 32 Tool | Arm Type 32 Tool |

| Maximum Tool Diameter | (75mm) 2.95" | (75mm) 2.95" | (75mm) 2.95" | (75mm) 2.95" |

| Maximum Tool Length | (300mm) 11.81" | (300mm) 11.81" | (300mm) 11.81" | (300mm) 11.81" |

| Maximum Tool Weight | (7Kg) 15.4 lb | (7Kg) 15.4 lb | (7Kg) 15.4 lb | (7Kg) 15.4 lb |

| Floor Spece L | (6232mm) 245" | (7232mm) 285" | (8232mm) 324" | (10260mm) 404" |

| Floor Spec W x H | (4430x3975mm) 174.4" x 156.5" | (4430x3975mm) 174.4" x 156.5" | (4430x3975mm) 174.4" x 156.5" | (4430x3975mm) 174.4" x 156.5" |

| Power Requirement | 220V, 3 Phase, 60Hz, 50KVA | 220V, 3 Phase, 60Hz, 50KVA | 220V, 3 Phase, 60Hz, 50KVA | 220V, 3 Phase, 60Hz, 50KVA |

| Machine Weight | (13000Kg) 28,600 lb | (19000Kg) 41,887 lb | (22000Kg) 48,400 lb | (22000Kg) 57,320 lb |

All Specification are subject to change without prior notice

| Standard Accessories | Optional Accessories |

|---|---|

| Built in Spindle 12000 RPM | Fully Enclosed Splash Guard |

| Spindle Oil Refrigeration Unit | Spindle Speed 15,000 20,000 RPM |

| Fanuc Oi-Mf Plus, 10..4" Color LCD | Coolant Through Spindle |

| 2 MB Memory | 4th Axis Complete |

| PCMCIA Slot for Memory Expansion | Data Server 2 GB (DNC) |

| High Precision Linear Way on X Axis | Fanuc 31i- F |

| Hardened Ground Box Ways on Y & Z | Arm Type 40 Tool ATC |

| Dual Spiral Type Chip Auger | Auto Tool Measuring System |

| Chain Type Chip Conveyor | 5 Face Machining |

| Semi Enclosed Splash Guard | Interchangable Spindle Head |

| Spindle Air Blast & Cutting Air Blast | |

| Arm Type 32 Tool ATC | |

| Auto Lubrication System | |

| Fanuc & Machine Manual |