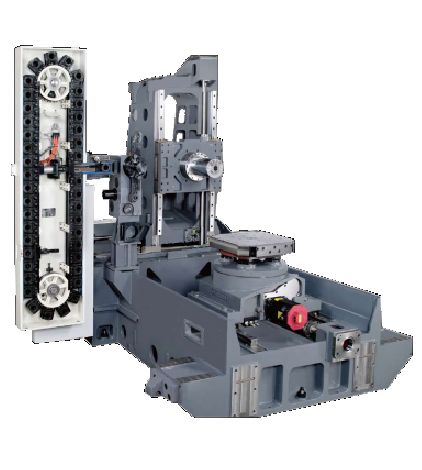

HT-500A

Category: CNC Horizontal Machining Center

- High-tensile Meehanite cast iron on all major parts, with 3 layers T shape box type one piece base design provides best rigidity and superior accuracy stability.

- Multi-layers and enforce-rib design on base unit structure prevent any deformation and greatly reduce machining vibration during high speed operation.

- Special differential-slide base design, Special High-Low level X axis guide way design with 580mm wide span providing best stability and resistance of column motion during high speed machining

- Superior high speed axial federate, Optional 45mm diameter P20 coolant through ballscrew design on all 3 axes provides highest rapid federate 2,340mm/min with minimum heat deformation during high speed operation

- Large Span Design, 720mm extra wide span between Z axis slides provides most stable movement and heavy machining operation support.

- Built-in spindle design, high torque build-in type direct drive spindle with P4 grade angular contact bearings in maximum loading support arrangement set up. Standard external spindle cooling system, air lock system on spindle nose and floating tool clamp/unclamp system provide lowest noise, minimum vibration and highly stable performance in high speed operation.

- Automatic pallet change system, high precision APC system adopts one-by-one table exchange way with table exchange time 11 seconds.

| Specification | |

|---|---|

| Travel X Axis | (800mm) 31.5" |

| Travel Y Axis | (800mm) 31.5" |

| Travel Z Axis | (800mm) 31.5" |

| Rapid Deed Rate X, Y and Z Axis | (60000mm/min) 2362ipm |

| Cutting Feed Rate | (30000mm/min) 1181ipm |

| Spindle Nose to Table Center (min./max.) | (150 - 950mm) 5.90" - 37.40" |

| Spindle Center to Table Surface | (120 - 920mm) 4.72" - 36.22" |

| Table Dimension | (500 x 500mm) 19.6" x 19.6" |

| Maximum Loading | (600Kg) 1,322lb |

| Table Index Resolution | 1˚ |

| Index Speed | 3.6 sec / rev. |

| Spindle Taper | CAT-40 |

| Spindle Motor | (11/15KW) 15/20HP |

| Spindle Speed | 12000RPM |

| Tool Selection | Shortest Path, Bi-Direction random type |

| Magazine Capacity | Arm Type 40 |

| Tool Change Time | 1.5 sec |

| Maximum Tool Dia. | (95mm) 3.74" |

| Maximum Tool Length | (400mm) 15.74" |

| Maximum Tool Weight | (11.0Kg) 24 lb |

| Floor Space W x D x H | (3100 x 6100 x 3000mm) 122" x 240.15" x 118.11" |

| Power Requirement | 220V, 3 Phase, 60Hz, 45KVA, 75Amp |

| Machine Weight | (13500Kg) 29,762 lb |

All Specification are subject to change without prior notice

| Standard Accessories | Optional Accessories |

|---|---|

| Arm Type 40 Tool ATC | Data Server 2 GB (DNC) |

| Fanuc Oi-MF Plus, 10.4" Color LCD | Coolant Through Spindle |

| 2 MB Memory | High Pressure Coolant System |

| PCMCIA Slot for Memory Expansion | Fanuc 31i-F |

| Spindle Oil Refrigeration Unit | Auto Tool Measuring System |

| Heat Exchanger for Electrical Cabinet | Chip Flushing System |

| Auto Lubrication System | CAT-50 |

| Spindle Air Blast & Cutting Air Blast | 45mm Diameter P20 Coolant Through Ballscrew |

| Spindle Air Curtain | Arm Type 60T |

| Magazine Operators Panel | Rotary table size 500x630mm |

| Fanuc & Machine Manual |