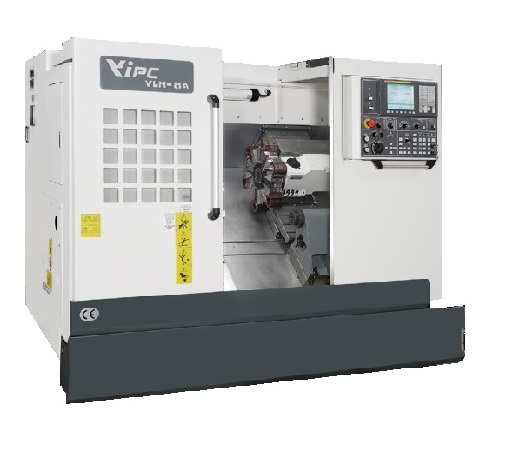

YLM-6

Category: CNC Turning Center

Rigid & Precise Spindle

- Spindle front side is specially adopted large diameter roller bearings and angular contact ball bearing to achieve the best cutting capacity. There's optimal span and balancing support between the front and rear roller bearings. This design resists the radial load and provides excellent cutting condition in high and low speed.

Rugged & Stable Base

- The powerful one-unity-shaped base structure is professionally developed by 3D-CAD and FEM analysis to let the inner walls be perfectly strengthened with rigid ribs. It increase whole machines rigidity and stability, keeps long term of reliable accuracy and extends tooling life. (Finite Element Method Drawing)

High Speed Servo Turret

- The turret rotation and indexing is driven by a powerful servo motor which provides accurate positioning, fast and stable tool change.

High Precision Ball Screw & Linear Guide

- Latest and durable linear guide provides smooth and fast movement, 30 m/min. rapid traverse reduces non-cutting time and increase productivity

Programmable & Hydraulic Tailstock

- The whole stiff tailstock is controlled by programming and hydraulic cylinder to reach smooth and fast movement along the linear guides and it gains steady clamping force and convenient operation.

| Specification | |

|---|---|

| Swing Over Bed | (460mm) 18.11" |

| Swing Over Cross Slide | (208mm) 8.19" |

| Maximum Turning Diameter x Full Length | (380x410mm) 14.96" x 16.14" |

| Distance Between Center | (525mm) 20.67" |

| Travel X Axis | (210mm) 8.26" |

| Travel Z Axis | (420mm) 16.53" |

| Rapid Travel X, Z | (30m/min) 1,180ipm |

| Bar Capacity | (45mm) 1.77" |

| Spindle Bore | (56mm) 2.20" |

| Spindle Nose | A2-5 |

| Spindle Motor | (9/11KW) 12/15HP |

| Spindle Speed | 6000RPM |

| Spindle Bearing Diameter | (90mm) 3.54" |

| No. of Station | 12 |

| Turning Tool Shank Size | 0.75" |

| Boring Bar Holder Size | 1.00" |

| Tailstock Travel | (445mm) 17.52" |

| Tailstock Quill Taper | M.T.4 |

| Floor Space (L x W x H) | (2400x1450x1760mm) 94.49"x57"x69.29" |

| Machine Weight | (3000Kg) 6,600 lb |

| Power Requirement | 220V, 3 Phase, 60Hz, 50Amp |

All Specification are subject to change without prior notice

| Standard Accessories | Optional Accessories |

|---|---|

| 6" 3 Jaw Hydraulic Chuck | Live Tooling with C Axis |

| 12 Station Servo Driven Turret | Auto Tool Presetter |

| 6 Set of Boring Bar Holder | Auto Door Open / Close |

| 6 Set of Taper Block for Turning Holder | Parts Catcher |

| One Set of Hard Jaw & Soft Jaws | Bar Feeder Interface |

| One Set of Bushing | Royal Live Center |

| Chain Type Chip Conveyor & Cart | Royal 5C Collet Chuck |

| Programmable Tailstock Body | Royal 16C Collet Chuck |

| Auto Lubrication System | Royal 3J Collet Chuck |

| Heat Exchanger for Electrical Cabinet | Steel Soft Jaw for 6" Chuck |

| Operator, Maintenance, Electrical & Part Manual | |

| Fanuc Operator & Maintenance Manual |